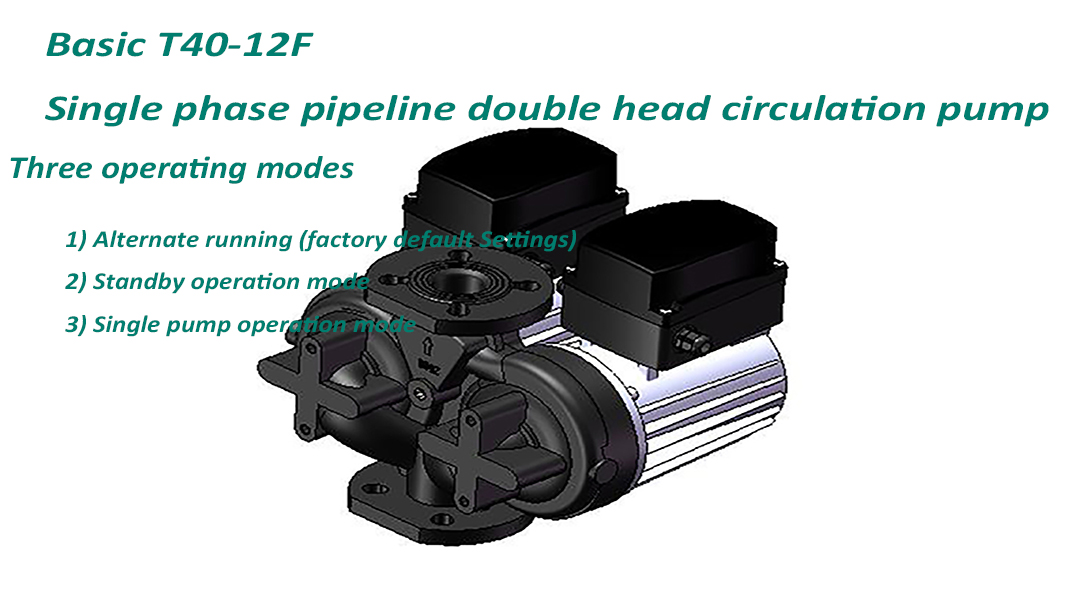

Shinhoo's Latest Innovation丨Basic T40-12F Single Phase Pipeline Double Head Circulation Pump

Shinhoo has once again taken a stride forward with their latest product release, Basic T40-12F Single Phase Pipeline Double Head Circulation Pump. This cutting-edge pump offers exceptional performance and versatility, making it an ideal choice for a wide range of applications in various industries.

Enhanced Functionality:

With relay modules installed in the junction boxes of the two-headed pump, Basic T40-12F presents a host of operating modes to suit different requirements. Users can effortlessly switch between three modes by selecting a designated switch:

1) Alternate running (factory default Settings)

The two pumps are operated alternately in the form of working pumps and standby pumps which each pump operate alternately every 24 hours. If the working pump stops running due to a fault or is manually shut down, the standby pump automatically starts running. The order of the working pump and the standby pump can be selected by selecting the switch.

2) Standby operation mode

Two pump heads, one as a working pump and the other as a backup pump. In this mode, the working pump will run continuously and will not perform periodic automatic alternating actions. If the working pump is out of operation for some reason, or is manually shut down, the standby pump will automatically start. The order of the working pump and the standby pump can be selected by selecting the switch.

3) Single pump operation mode

One pump operates independently and does not communicate with the other pumps. In this mode, if the working pump stops running due to a fault or is manually shut down, it will not automatically switch to another pump.

Versatile Applications:

Basic T40-12F excels in a multitude of applications, making it a versatile choice for diverse settings. It seamlessly integrates into both single and double pipe heating systems, delivering efficient circulation and precise temperature control. Additionally, its robust design enables it to be employed in large-scale systems, such as those found in urban apartments and suburban villas, including residential water supply booster, geothermal systems, hot water circulation, liquid circulation in cooling and air conditioning systems, and even boiler solar water supply.