In the wiring harness industry, wire as the core component, its performance is directly related to the overall performance of the wiring harness system. From automobiles to electronic equipment, from industrial machinery to aerospace fields, wires bear the heavy responsibility of transmitting current and signals in various wiring harness application scenarios, just like nerves and blood vessels in the human body, ensuring smooth information and stable power transmission between various systems.

Key characteristics and engineering verification of wire conductors:

(1) The ultimate pursuit of electrical performance

In the automotive wiring harness laboratory built by Aichie, the conductor conductivity must be verified according to IEC 60228 standards:

High purity copper conductor: using 4N grade oxygen-free copper (purity ≥99.99%), which reduces the resistivity to 1.724×10⁻⁸Ω·m, reducing energy consumption by 15% compared with conventional copper. In the new energy vehicle 800V high voltage platform harness, this optimization can reduce the charging loss by 2.3%.

Intelligent insulation system: Crosslinked polyethylene (XLPE) is combined with ceramic filler through a three-layer co-extrusion process to increase the pressure level to 3000V/mm. The charging wiring harness developed by Aichie Zhizao for a German car company still maintains the insulation resistance > 500MΩ·km under the working condition of -40℃~150℃.

(2) Breakthroughs in the scenization of physical properties

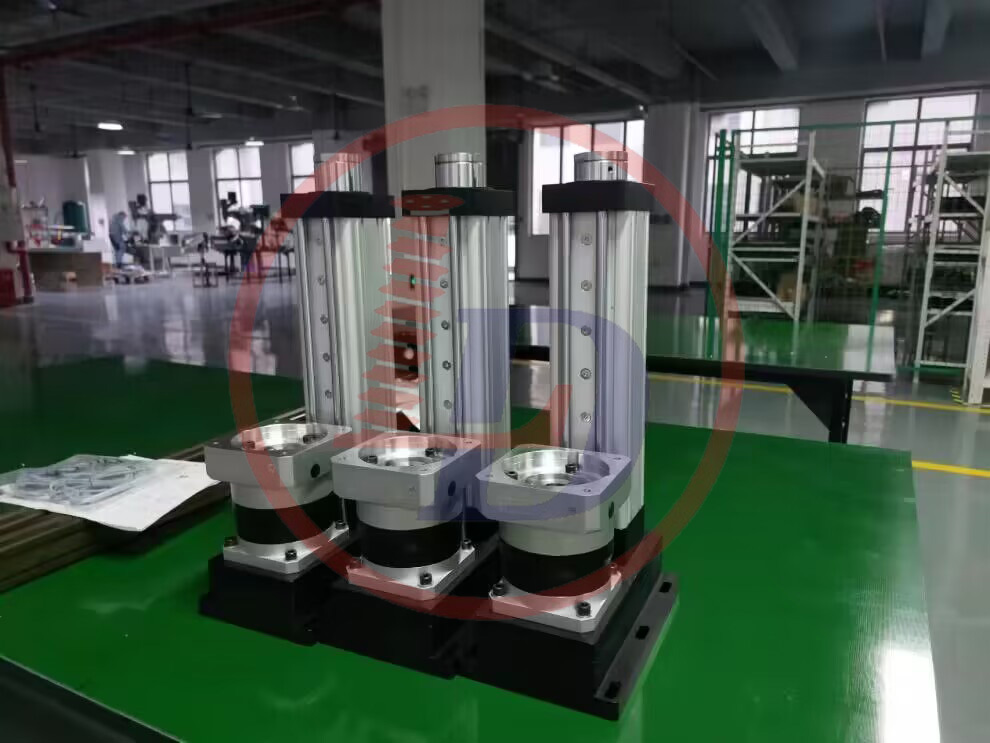

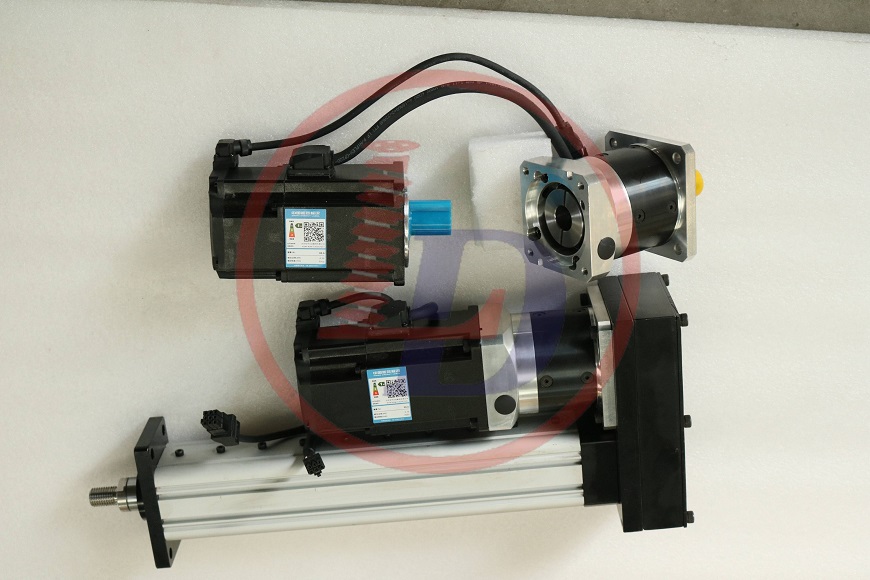

In the field of industrial robot joint harness, Aichie Intelligent innovation application multi-dimensional testing:

Dynamic bending test: Based on the VDA 235-106 standard, 1 million ±180° bending tests are carried out on the multi-stranded copper wire to ensure that the breakage rate of the wire is < 0.1%.

Composite reinforced structure: The combination design of aramide fiber reinforced layer and silver-plated copper conductor makes the tensile strength of the wire reach 600MPa, which has been successfully applied to the spacecraft solar panel drive wire harness.

(3) Strict verification of environmental adaptability

For the tropical automotive market, Aichie has developed special protective wires:

Salt spray test: 2000 hours of test under ASTM B117 standard, tinned copper conductor corrosion area rate < 5%.

Oil resistant solution: Using polyamide (PA) insulation layer, the volume expansion rate is < 3% after 1000 hours of oil immersion at 120℃, has been used in batches for heavy truck engine wiring harness.

Cable selection: Select the cable type based on the application scenario

Automotive industry: In the engine compartment, due to high temperature, vibration, oil and other complex environment, high temperature, oil and vibration resistant wires are often used, such as German standard FLRY-A and other models of wires; The door wiring harness needs to be bent due to frequent switching, and more flexible AVSS (thin insulated) wires are used. For sensors that transmit weak signals, such as knock sensors and crankshaft position sensors, electromagnetic shielding wires are required to prevent electromagnetic interference.

In the field of electronic equipment: In the miniaturized and high-performance electronic equipment such as mobile phones and tablet computers, the wires need to have the characteristics of small size, high precision and good flexibility. For example, FFC (flexible flat cable) terminal line can be arbitrarily selected the number and spacing of wires, greatly reducing the volume of electronic products, often used for motherboard and display, camera and other components to connect to achieve signal and power transmission.

Industrial equipment: industrial automation production line environment is complex, large vibration, strong electromagnetic interference. Wires used to connect industrial robots, CNC machine tools and other equipment, in addition to good electrical performance, but also need to have a high anti-interference ability and resistance to harsh environment, such as the use of double-layer shielded wires to resist electromagnetic interference, the use of wear-resistant, corrosion-resistant materials to deal with harsh industrial environments.

Aerospace: Aerospace wire harness wire requirements are very strict, need lightweight, high strength, high temperature resistance, radiation resistance. Wires are mostly made of special alloy materials and advanced manufacturing processes, such as silver-plated copper wires, which can ensure good electrical conductivity and reduce weight; The insulation material is made of polyimide and other high-performance materials to adapt to the extreme space environment and complex working conditions at high altitude.

The development trend of wire

(1) Research and development and application of high-performance materials

With the continuous improvement of wire performance requirements in various industries, the development of new high-performance materials has become a trend. In terms of conductor materials, in addition to optimizing the performance of copper and aluminum, the exploration of new conductive materials, such as carbon nanotube composite materials, is expected to achieve higher conductivity and better comprehensive performance. In the field of insulation materials, the research and development of materials with higher temperature resistance, radiation resistance and anti-aging properties, such as new ceramic based insulation materials, high-performance fluorine plastics, etc., to meet the needs of high-end fields such as aerospace and new energy vehicles.

(2) Miniaturization and lightweight design

In order to adapt to the development trend of miniaturization of electronic products and lightweight of automobiles, wires are developing in a thinner and lighter direction. On the one hand, by improving the manufacturing process, the diameter of the wire and the thickness of the insulation layer are reduced under the premise of ensuring the electrical and physical properties. On the other hand, the use of lightweight materials to replace the traditional heavier wire materials, such as in aerospace wire harnesses, the use of lightweight alloy wires and low-density insulation materials, while reducing the weight of the wire harness, without affecting its performance, improve the overall competitiveness of the product.

(3) Intelligent and multi-function integration

In the future, wires will not only be limited to the transmission of current and signal functions, and intelligent and multifunctional integration will become the development direction. For example, the research and development of a wire with self-monitoring function can monitor the temperature, current and other parameters of the wire in real time, once there is an abnormal early warning, improve system safety and reliability; The wire is integrated with sensors, communication modules, etc., to realize the integration of data acquisition, transmission and processing, and to provide support for the development of smart devices and smart grids.

Wire as the key basis of the wire harness industry, its performance, selection and development are closely related to the technical progress and product upgrades in various application fields. Continuously improving wire performance, optimizing selection criteria, and keeping up with development trends are the core driving forces for the continuous innovation and development of the wire harness industry.

In the wave of electrification and intelligence, Aichie will continue to deepen the core technology of wire research, to provide global customers with more reliable, more cost-effective wire harness solutions.