What is the history of neodymium magnets?

High quality neodymium magnets, known for their remarkable strength and versatility, have a fascinating history that traces back to the mid-20th century. Discovered during a time of intense research into rare earth elements, these magnets have transformed industries ranging from electronics to renewable energy, revolutionizing applications and driving innovation in countless fields.

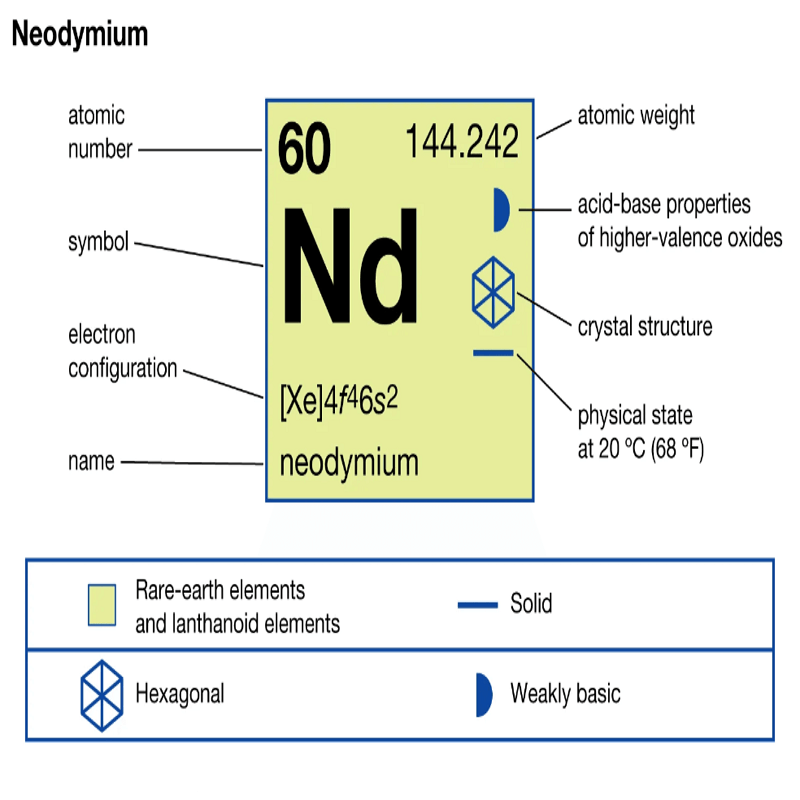

The story begins in the late 1950s when a team of researchers, including Dr. Shuji Nakamura and Dr. Masato Sagawa in Japan, began experimenting with neodymium, a rare earth element. Their goal was to create stronger magnets than those available at the time, which primarily consisted of ferrite and alnico. In 1983, they succeeded in developing the first neodymium-iron-boron (NdFeB) magnet, a breakthrough that would change the landscape of magnet technology.

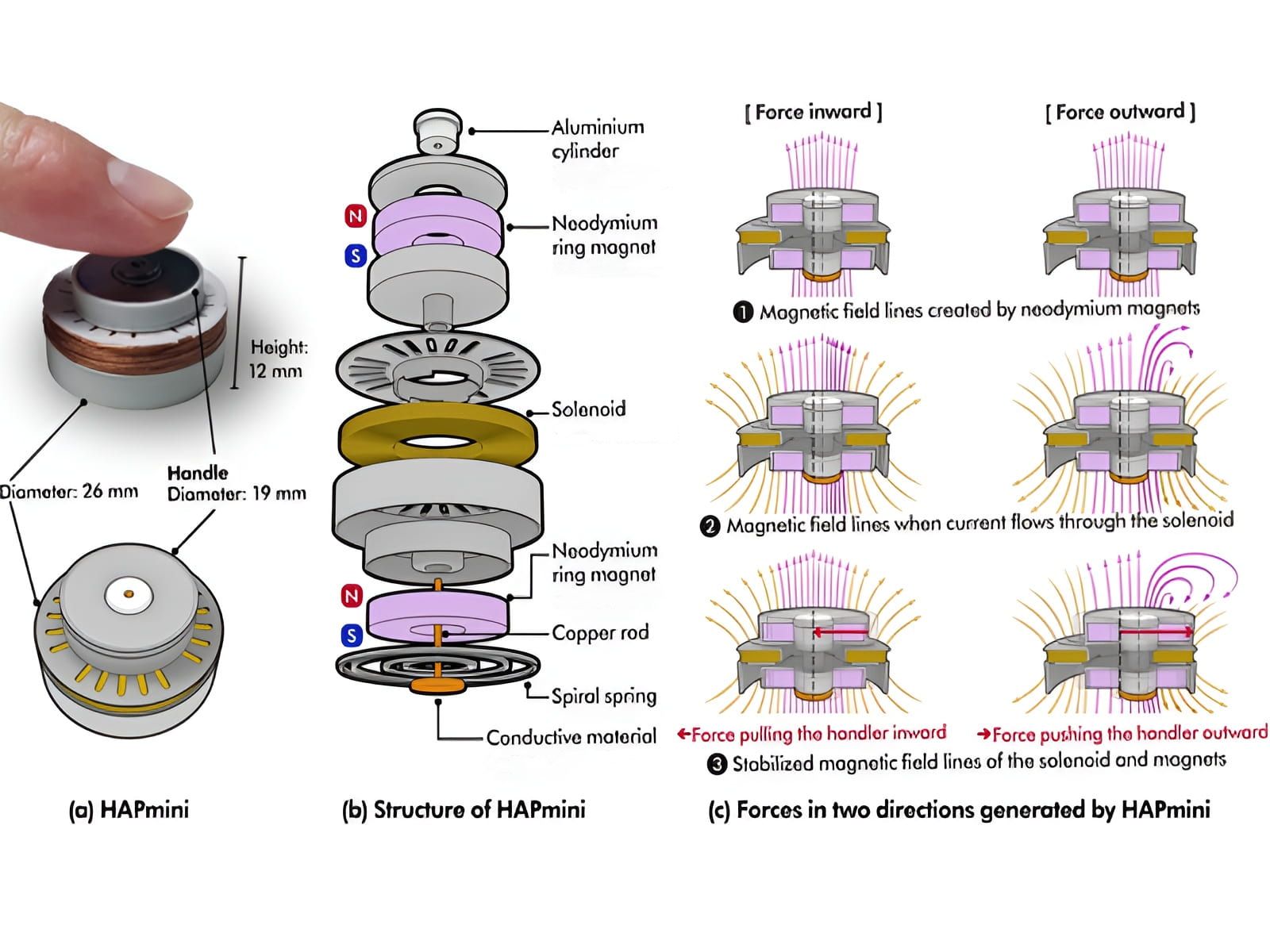

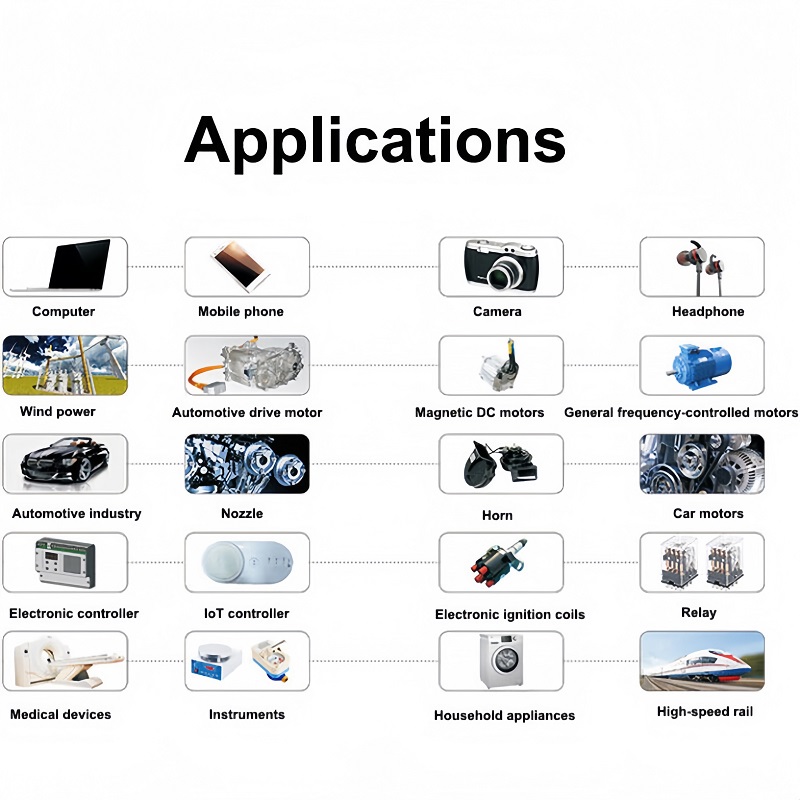

The unique properties of good performance neodymium magnets stem from their composition. Combining neodymium with iron and boron creates a powerful magnetic material that retains its magnetism even under high temperatures. This characteristic makes NdFeB magnets ideal for a wide range of applications, including electric motors, hard disk drives, and various consumer electronics,ultimately enhancing performance and efficiency in modern technology and paving the way for advancements in innovation.

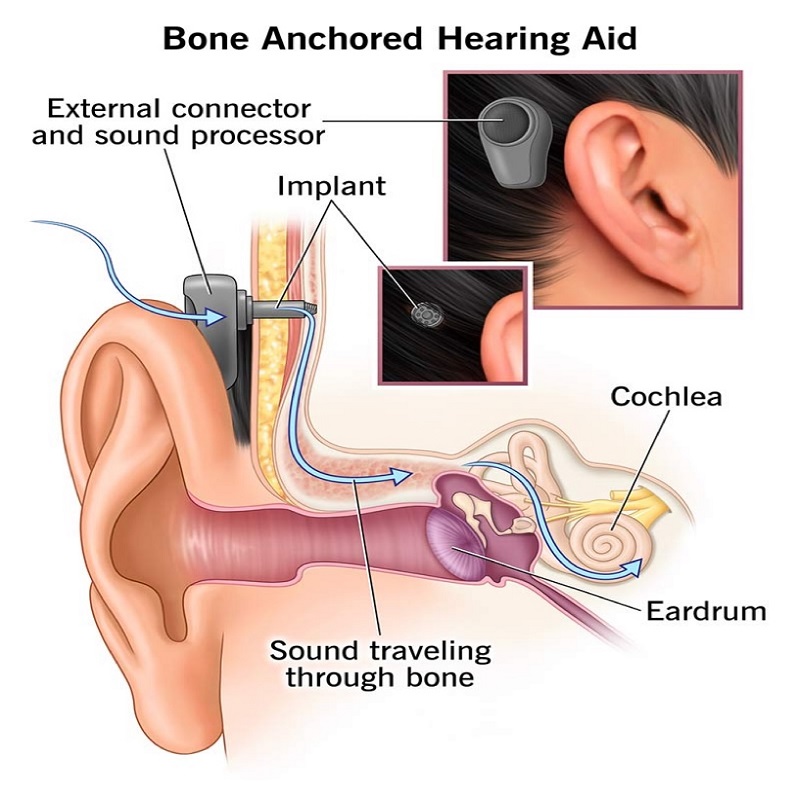

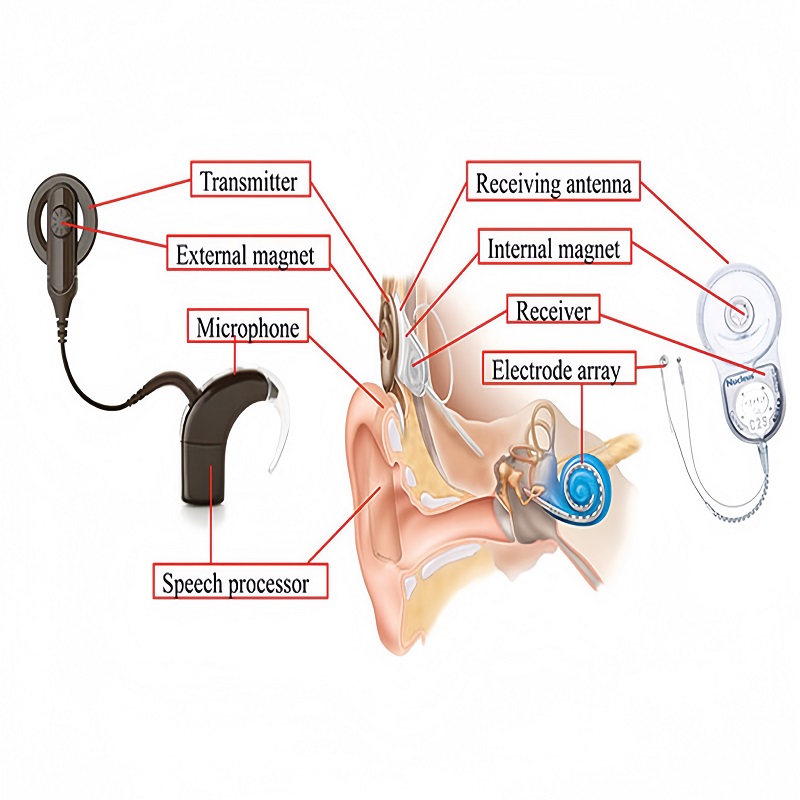

The commercialization of neodymium magnets began in the 1980s, leading to widespread adoption across industries. Companies recognized their potential for miniaturization, allowing for smaller, lighter devices without sacrificing performance. This innovation was crucial in the development of compact audio equipment, computer hardware, and even medical devices, where space and weight constraints are paramount.

As demand for strong rare earth magnets surged, so did the interest in their environmental impact and supply chain. Neodymium is primarily sourced from China, raising concerns about sustainability and resource management. In recent years, researchers and manufacturers have focused on developing recycling methods and exploring alternative materials to ensure the longevity of this vital resource.

Today, neodymium magnets are ubiquitous, found in everything from smartphones to electric vehicles. Their history reflects a remarkable journey of innovation, driven by the pursuit of strength and efficiency. As technology continues to evolve, the legacy of neodymium magnets will undoubtedly play a pivotal role in shaping the future of various industries.