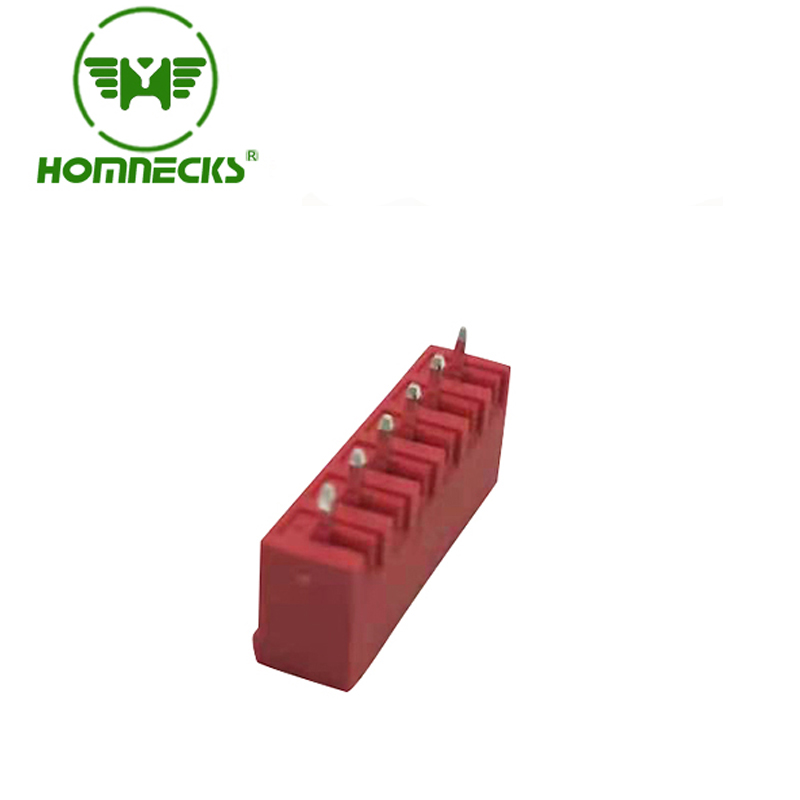

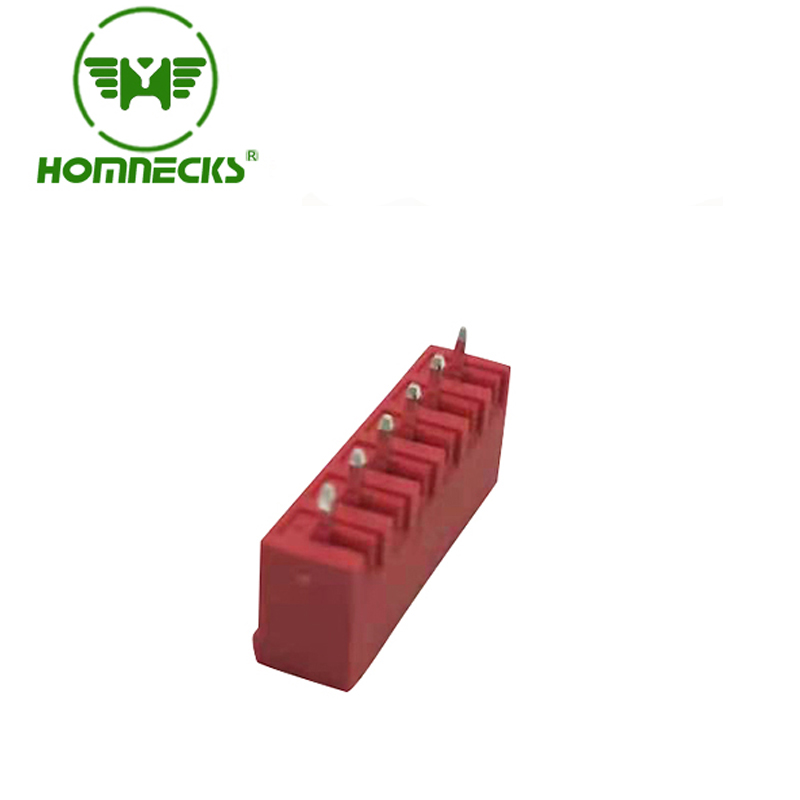

HongYi Electronic Co.,Ltd Pluggable terminal block is composed of two parts that are connected by plugging and unplugging. 3 pin screw terminal block connector One part compresses the wire and then plugs it into the other part, which is soldered onto the PCB board. This bottom mechanical principle and anti vibration design ensure the long-term airtight connection of the product and the reliability of the finished terminal block connector 3 pin. Both ends of the socket can be equipped with matching ears, which can greatly protect the contacts and prevent poor arrangement of the contacts. At the same time, this socket design can ensure that the socket can be correctly inserted into the mother body. HongYi Electronic Co.,Ltd socket can also have assembly buckles and locking buckles. The assembly buckle 3 pin terminal block connector can provide a more stable fixation to the PCB board, and the locking buckle can lock the mother body and socket after installation is completed.

HongYi Electronic Co.,Ltd Various socket designs can be paired with different insertion methods for different substrates, such as horizontal, vertical, or tilted towards the printed circuit board. You can choose either metric line gauges or standard line gauges.

The main reason 3 pin screw terminal for the deformation problem of long digits in the combination of spliced products is also due to the unreasonable structure, 3 position terminal block which leads to an imbalance of forces on the two spliced falcons in the front, back, up, down, left, and right directions. Therefore, the stress and deformation direction of the spliced falcons should be considered in the structural design.

2. Regarding the issue of screw anti drop, I suggest using neck anti drop as much as possible, as it avoids the trouble caused by tolerance accuracy at the screw rod and collar compared to collar anti drop. And the structure is reliable and the tolerance is easy to control.

3. Regarding the issue of salt spray testing on 4 pin terminal and threaded steel parts after electroplating, HongYi Electronic Co.,Ltd according to the current company's standard for thread electroplating (the coating is limited, but the thickness of the coating corresponding to the size of the thread still needs to be further determined), there are two methods to solve this problem under normal electroplating process: selecting the correct sealing agent and using multiple electroplating of the coating. Both methods aim to cover the pores generated by screws that are not visible to the naked eye. The cost of using multiple electroplating layers is relatively high, so it is recommended to use the first method, and the key to this method lies in the study of the sealing agent formula.

4. The issue of insertion and extraction force involves a lot of content, HongYi Electronic Co.,Ltd which is related to materials, electroplating, structure, and the industry in which it is applied. It is an important mechanical performance requirement in the connector industry, especially for plug-in terminals. The selection of materials is limited by conductivity (current), contact resistance, and temperature rise in terms of insertion and extraction force. I won't go into detail here. Electroplating is mainly influenced by the type of coating and whether it is pre plated or not,

HongYi Electronic Co.,Ltd Only by doing well, strengthening, and expanding the products within our capabilities. To win the favor of customers, enhance the influence and brand awareness of the enterprise in the industry, Shanghai Youle Electric follows this rule and strives to abandon old-fashioned marketing concepts in the fierce competition of the plug-in terminal market, focusing on terminal brand marketing to win a larger and broader market.