How Heat Affects Grinding Tool Performance

Heat is an inevitable result of the grinding process. When abrasive tools come into contact with surfaces like concrete, terrazzo, or stone, the friction generated can cause temperatures to rise significantly. While some heat is normal, excessive heat can harm both the grinding tool and the material being worked on, decreasing efficiency and causing premature wear.

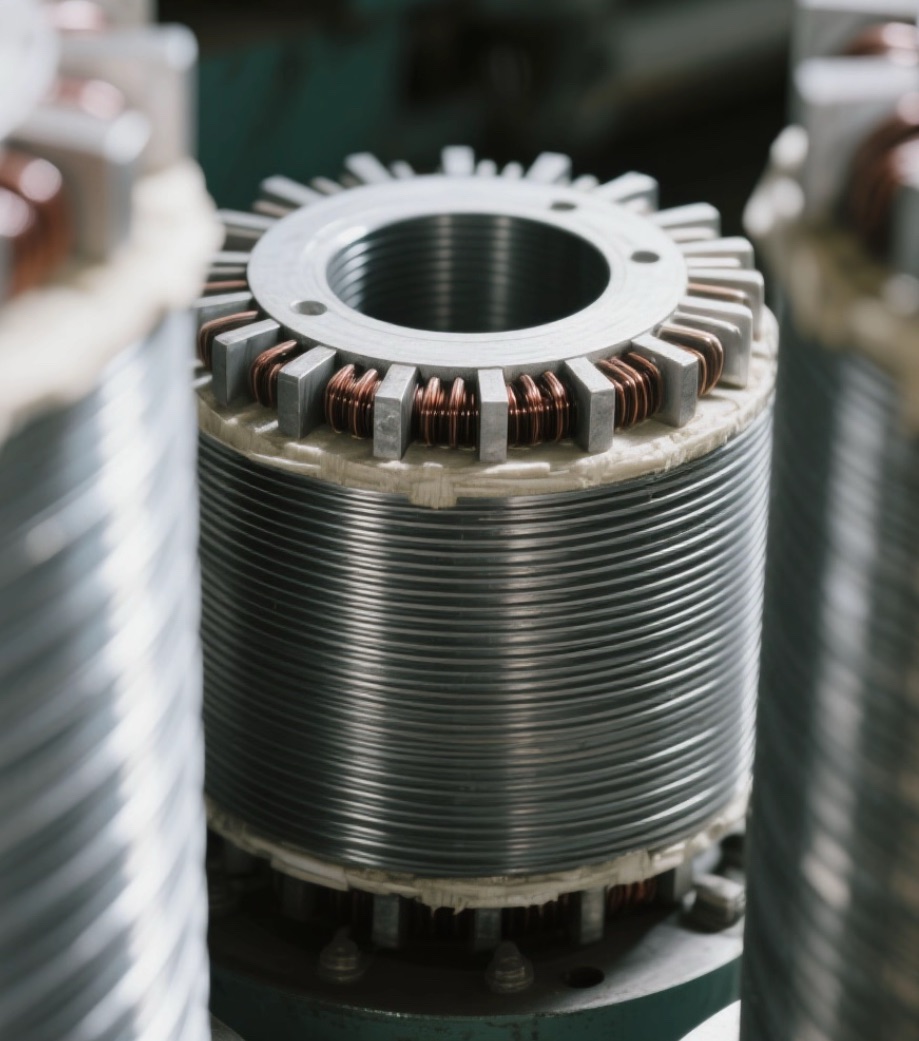

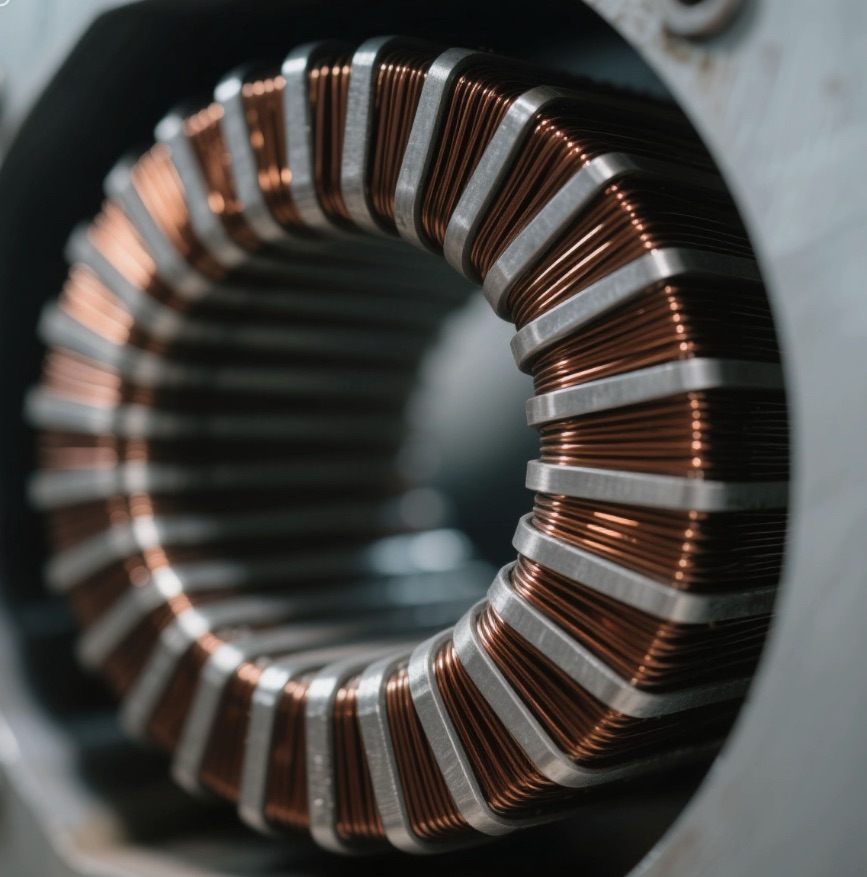

One major effect of heat on grinding tools is the softening of the bond that holds the abrasive segments together. In metal bond tooling, high temperatures can cause the bond to release diamonds too quickly, reducing the tool’s lifespan. resin pads for concrete polishing are particularly sensitive to heat; excessive heat can melt or smear the resin, leading to glazing and diminished polishing performance.

Heat can also damage the surface finish. Grinding at elevated temperatures may cause the material to burn or discolor, which is especially problematic in decorative concrete or terrazzo applications where appearance is important. Overheating can also cause microcracks in brittle materials, which might not be immediately visible but can lead to long-term structural problems.

To maintain tool performance, proper cooling and pressure control are crucial. Wet grinding is a common method to dissipate heat and prolong tool life. In dry grinding, using high-quality, heat-resistant NewGrind diamond grinding tooling along with vacuum systems to remove dust and heat can help prevent damage.

Operators should monitor machine speed and pressure settings carefully. Applying too much pressure or running the machine too fast increases friction and heat buildup. Regular inspection of both the tool and the work surface can help detect early signs of heat-related damage.

By understanding how heat affects grinding tools, contractors can make better decisions on the job. Effectively managing heat leads to improved finishes, longer tool life, and greater productivity, while avoiding the hidden costs associated with overheating.