The transformer core (also known as the magnetic core) is the central magnetic circuit component of a transformer. Its material selection directly affects the transformer's efficiency, losses, and applicable scenarios. Based on operating frequency, power requirements, and cost factors, core materials can be categorized into the following types:

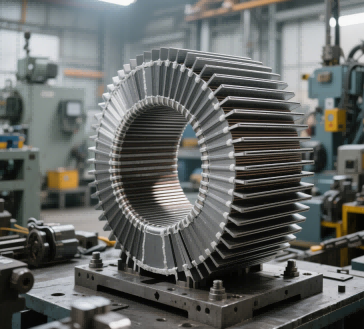

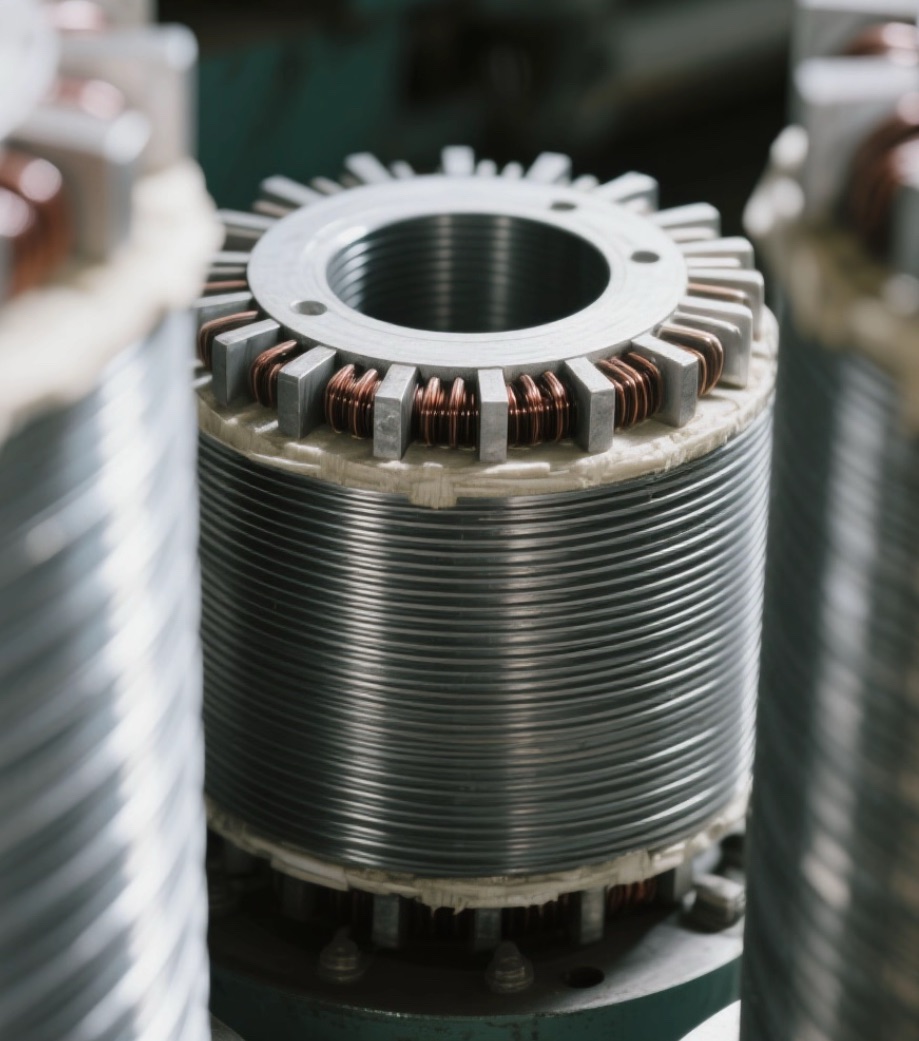

1. Traditional Silicon Steel Sheets (Fe-Si Alloy):

Composition:

Cold-rolled steel sheets with silicon content ranging from 0.8% to 4.8% , typically with a thickness of 0.35mm or thinner.

Characteristics:

High saturation magnetic induction (Bs≈1.6–1.7T), suitable for high-power scenarios at power frequencies (50/60 Hz).

Laminated stacking: Insulating coatings are applied between layers to reduce eddy current losses. However, losses increase significantly at high frequencies.

Applications:

Primarily used in power transformers and motor cores for low-frequency, high-power electrical equipment.

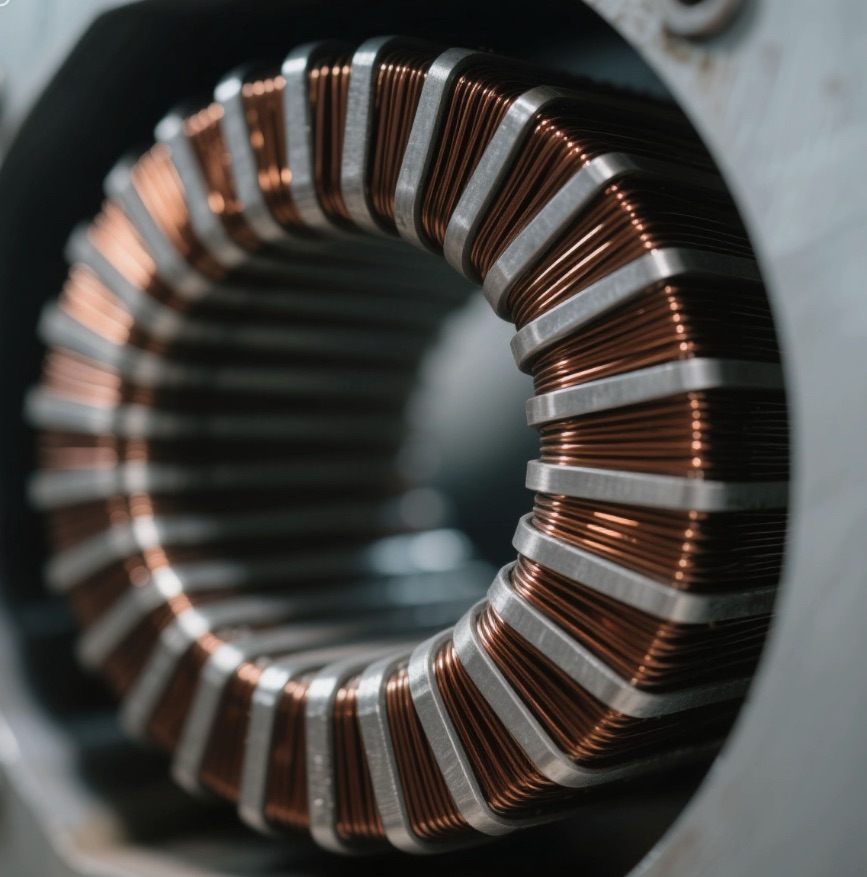

2. Ferrite Core

Composition:

Manganese-zinc (MnZn) or nickel-zinc (NiZn) ferrite, classified as sintered magnetic metal oxides.

Characteristics:

High resistivity: Significantly reduces eddy current losses at high frequencies, suitable for a frequency range of 1 kHz——1 MHz .

Low saturation flux density (Bs ≈<0.5T), weak DC bias capability, and prone to magnetic saturation.

Applications:

Widely used in electronic devices such as switch-mode power supplies (SMPS), high-frequency transformers, and inductors.

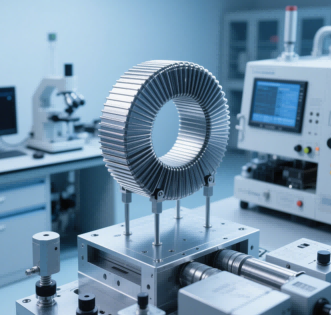

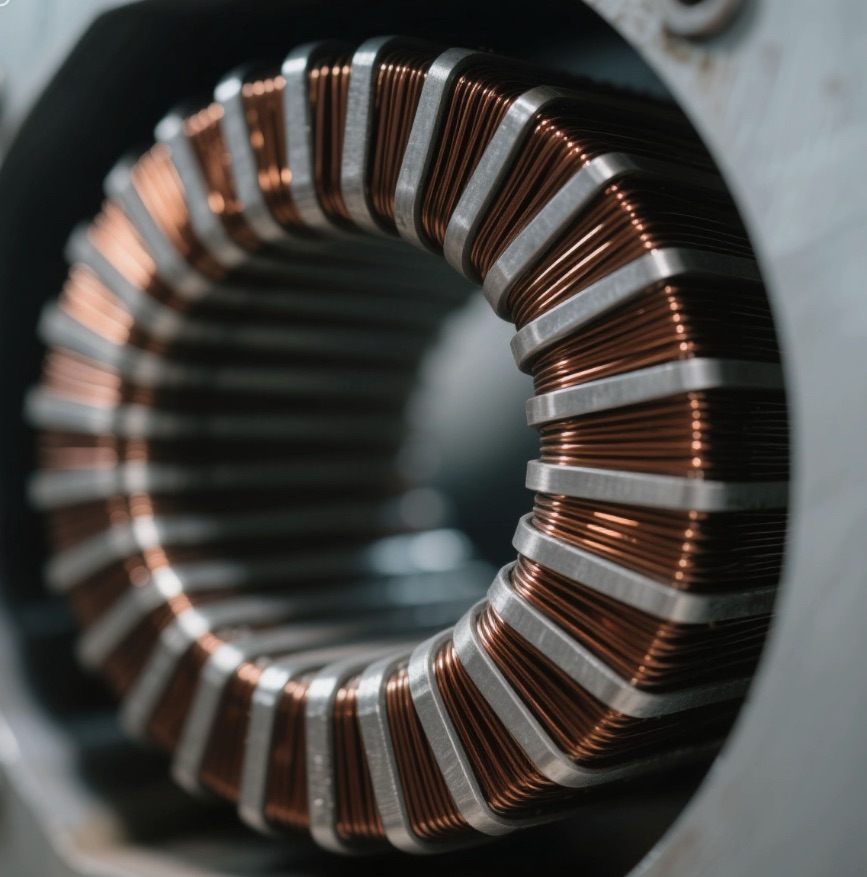

3. Metal Magnetic Powder Cores

Types:

Iron powder cores

Iron-silicon-aluminum powder cores (FeSiAl)

High-flux powder cores (HighFlux)

Molybdenum permalloy powder cores (MPP) .

Characteristics:

Strong anti-saturation capability: Reduces eddy currents through insulation-coated dispersed magnetic particles, making it suitable for DC superposition scenarios .

Medium permeability (μe≈10—125) with a frequency range of 10 kHz - 100 kHz .

Applications:

Widely used in medium-to-high-frequency power devices such as:

PFC inductors (Power Factor Correction)

Filter inductors.

4. Novel Alloy Materials

Amorphous Alloys

Composition:

Iron-based (e.g., Fe₈₀B₁₀Si₁₀) or cobalt-based amorphous ribbons, characterized by disordered atomic arrangement .

Advantages:

Ultra-low core losses (only 1/5 of silicon steel), enabling significant energy savings .

Limitation:

Significant magnetostriction (resulting in higher operating noise) .

Applications:

Energy-efficient distribution transformers.

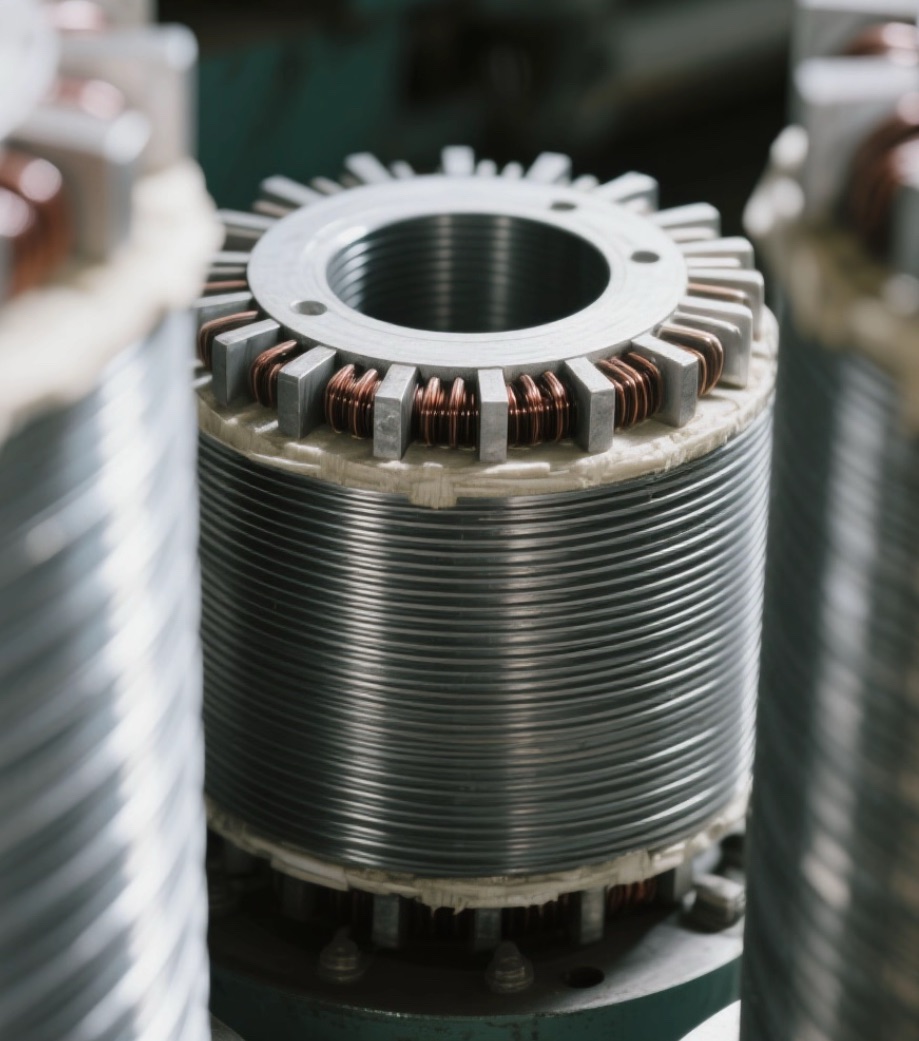

Nanocrystalline Alloys

Structure:

Nano-scale crystalline grains (<50 nm) embedded in an amorphous matrix .

Advantages:

High permeability & low losses (superior to ferrites at 50 kHz) .

Strong harmonic resistance and excellent thermal stability (operating range: -40–120°C) .

Applications:

High-frequency transformers and PV inverters .

EV electric drive systems (e.g., integrated OBC/DC-DC modules)

Key Factors in Material Selection

Operating Frequency

Low Frequency (≤1 kHz) :

Silicon Steel or Amorphous Alloys (e.g., Fe₈₀B₁₀Si₁₀).

High Frequency (>10 kHz) :

Ferrite Cores (MnZn/NiZn) or Nanocrystalline Alloys.

Loss Requirements

Lowest Core Loss:

Amorphous/Nanocrystalline Alloys.

High-Frequency Loss Optimization:

Ferrites.

Cost and Process

Cost-Effectiveness & Maturity:

Silicon Steel.

High Initial Cost with Long-Term ROI:

Amorphous/Nanocrystalline Alloys.