What should you pay attention to when using the screw jack? This is also crucial for us who often use jacks .It enables us to better understand the screw jacks, thus reducing unnecessary troubles during use.

The specific precautions for the screw jack are as follows:

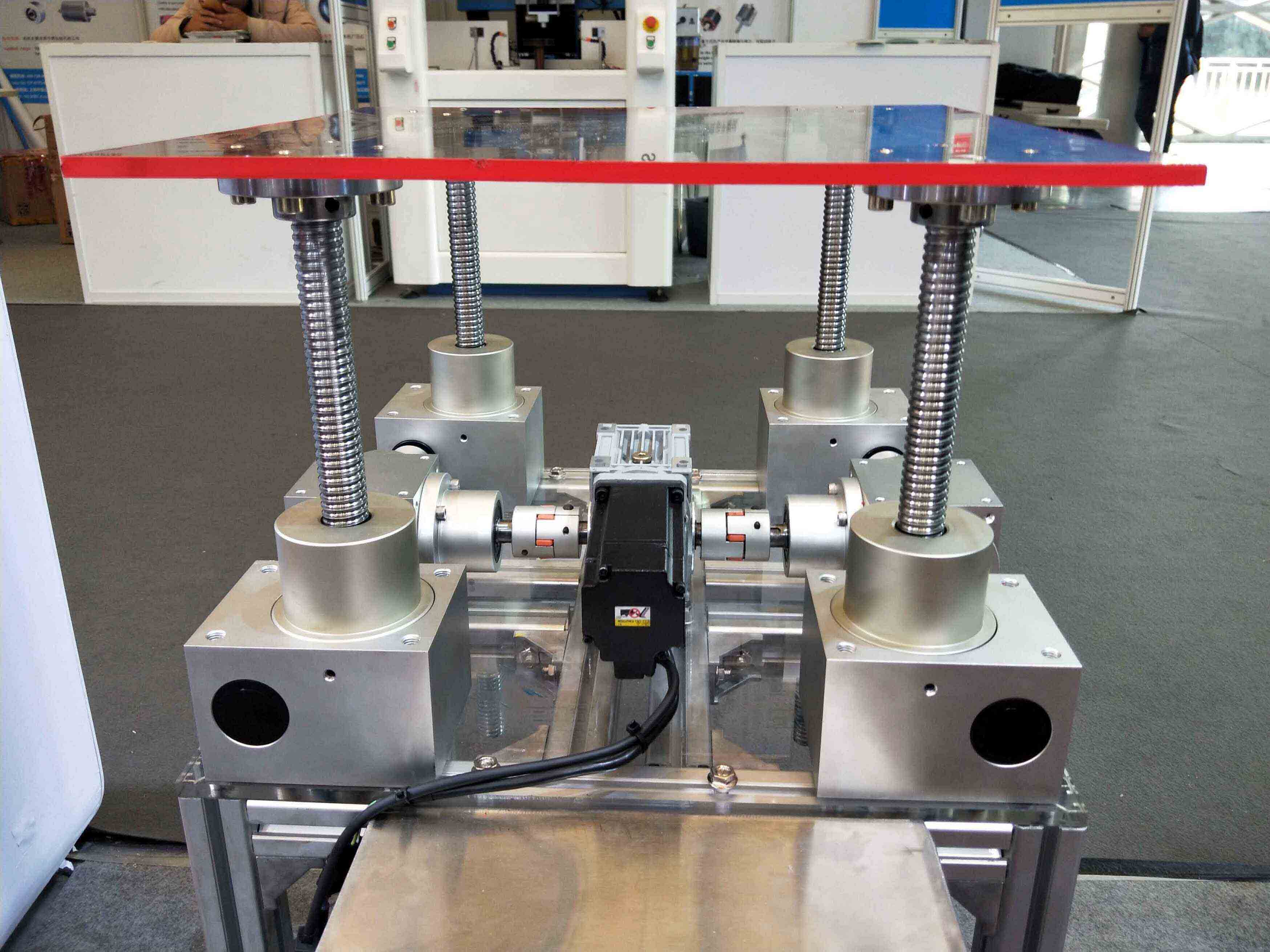

Firstly, always keep the surface of the screw jack clean, regularly check whether the internal structure is intact, make the pinion in the rocker flexible and reliable, and lift the lifting sleeve freely.

Secondly, the friction surface between the lifting sleeve and the housing must be oiled at any time. Other oil filling holes should be lubricated regularly.

Thirdly, in order to take into account the safety in use, the jack should not be overloaded, work with illness, it is not appropriate to use more than one to avoid danger.

Fourthly, The screw jack must be checked regularly, depending on the level of use and the working environment. It is advisable to check if there is a lubricant leak in the housing. If this happens, you need to find and remove the cause and fill the lubricant with the correct level.The lubrication conditions of the threaded spindle must be checked regularly (if necessary, recovery must be made) and the presence of any foreign matter. Safety components must be inspected according to applicable specifications.