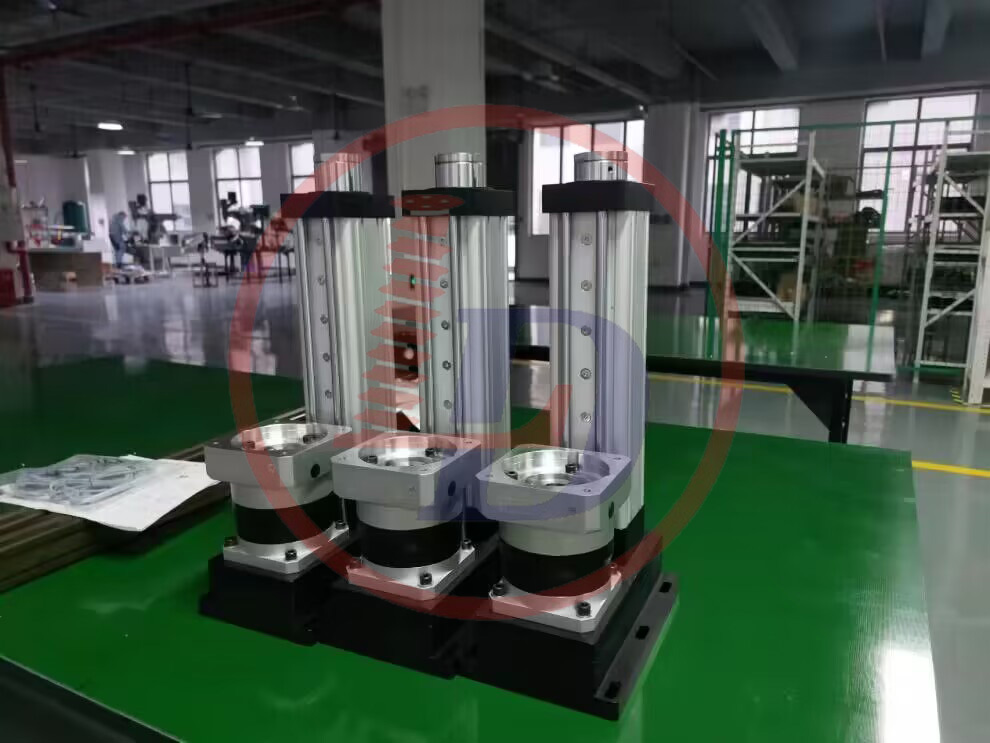

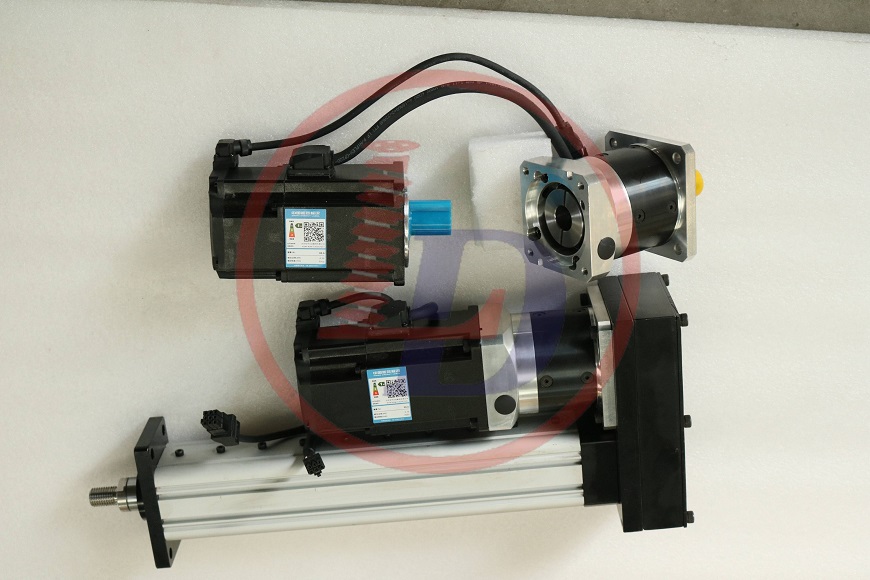

Screw stability verification: known load 100KN, stroke 500mm, speed 60mm/min, no guide rail, usage coefficient 1.5, low operating frequency, calculated model For (Heavy Duty Electric Linear Actuator model SCA200-V1-500-FL-P2):

lifting Screw specification Tr80*12

1. Known conditions

Load F=100KN=100,000N

Stroke S=500mm

Speed v=60mm/min

Usage coefficient K=1.5

Screw specification Tr80*12 (diameter 80mm, pitch 12mm)

2. Analysis of screw force

The screw mainly bears the axial load, so we need to calculate the stress of the screw under the axial load.

• Screw diameter d=80mm=0.08m

•Screw cross-sectional area A=π (2d)2= π(20.08)2=0.005027㎡

•Axial load Fax=K*F=1.5×100,00N=150,000N

3. Calculation of screw stress

Screw stress o =AFax=0.00502715000=2983866.67Pa

4. Check the stability of the screw

For the stability of the screw, we mainly pay attention to whether it will flex. Since the screw is usually installed on the fixed bracket and its length is relatively short (500mm), the possibility of buckling is relatively small. However, in order to evaluate more accurately, we can use Euler's formula to estimate the critical bending load of the screw.

1. Screw length=500mm=0.5m

2. The elastic modulus of the screw material E (set to steel, E≈210GPa=210×109Pa)

3. Screw moment of inertia I=π 64d4= π64×(0.08)4=2.01062×10-7m4

Eular critical load Fcr can be calculated by the following formula:

Fcr=12 π2EI=(0.5)2π 2×210×109×2.01062×10-7=2,649,444.44N

Because Fax=150,000N<Fcr=2,649, 444.44N, the screw is stable under axial load.

5. Summary

After calculation, it is confirmed that the screw (specification is Tr80*12) equipped with the linear actuator model SCA200-V1-500-FL-P2 is at a load of 100KN, stroke of 500mm, speed of 60mm/min, and a coefficient of use of 1.5 And the linear actuator is stable under the condition of low working frequency.