1. Definition and Core Components

• Basic Composition: With iron (Fe) as the base, it adds 2.8% to 3.5% silicon (Si), along with trace amounts of carbon, aluminum, manganese, and other elements. The addition of silicon significantly increases the resistivity (reducing eddy current losses) while maintaining high magnetic permeability.

• Grain Orientation: Through cold rolling and annealing processes, a Goss texture ((110)[001] crystal orientation) is formed, concentrating the magnetization direction highly along the rolling direction, and the magnetic permeability can be 3 to 5 times higher than that of non-oriented steel.

2. Key Steps of Production Process

Hot rolling: Initial forming to a thickness of 2-3mm.

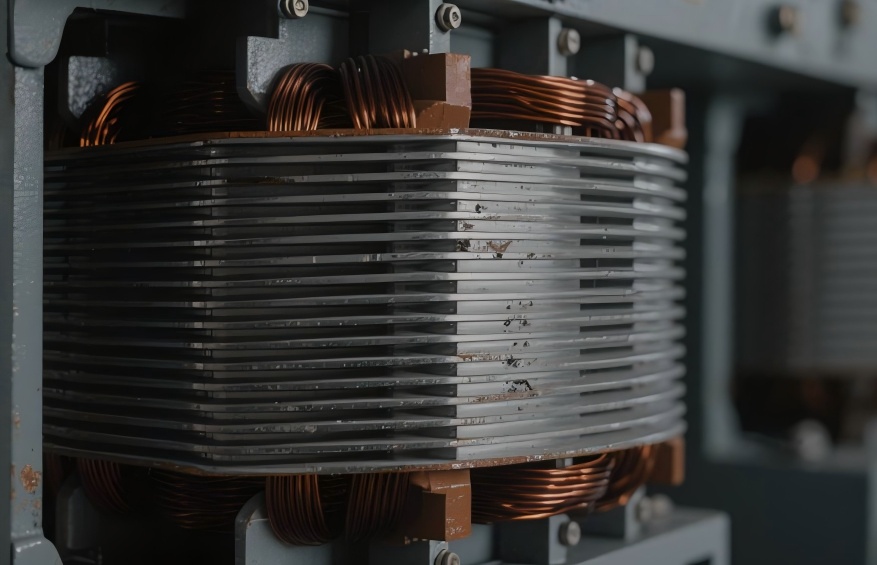

Cold rolling: Rolling at room temperature to the target thickness (0.18-0.35mm), with a compression ratio over 80%, and preliminary induction of grain orientation.

Annealing treatment:

• Primary annealing: Elimination of cold rolling stress.

•Secondary recrystallization annealing: At high temperatures (>1200°C), to align grains completely along the rolling direction, which is the core process.

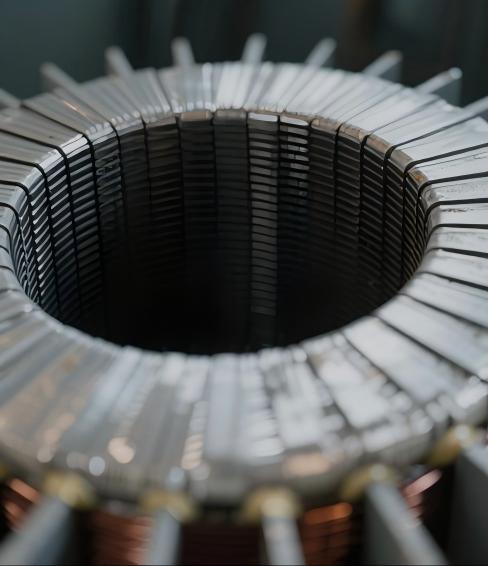

Insulation Coating: Surface coating with phosphate or ceramic layers to reduce eddy currents between laminations and prevent corrosion.

3.Performance Advantages

•Low iron loss: Grain orientation reduces hysteresis loss, with typical iron loss values being over 50% lower than those of non-oriented steel.

•High magnetic saturation strength: Reaching 1.8 - 2.0T, it supports efficient energy transmission.

•Low magnetostriction: Reduces vibration noise by 30 - 50dB, suitable for quiet environments (such as transformers in residential areas).

•High stacking factor: >95%, allowing for compact design and saving material space.

4.Application Fields:

•Power transformers: The core accounts for 70% of the cost, and CRGO steel can improve efficiency to over 99%.

•Renewable energy equipment: Wind turbine generators, electric vehicle motors (high power density).

•Precision instruments: MRI equipment, high-precision sensors (reliant on magnetic field stability).

5.Future Development Trends

•Ultra-thin development: Advancing 0.10–0.18mm thickness for application in micro electronic transformers.

•Coating technology: Nano-insulating layers to further reduce eddy current losses.

•Green manufacturing: Scrap steel recycling rate >90%, reducing carbon footprint.